High Temperature Insulation

We can provide and install high temperature insulation materials to suit a wide range of industrial plant and equipment. From steam boilers to coffee roasters, generators and engine exhausts to gas turbine ductwork, furnaces to plastic extruders, including processes operating in excess of 1000°C.

By using appropriate materials and installation techniques we help ensure that your expensive energy stays where it should be:- Working for You.

Typical Projects:

- Steam Boilers and Pressure Vessels. A comprehensive on site service for the insulation of new boilers and re-insulation of existing following maintenance and repair. We are able to modify existing insulation and cladding to include inspection points for the NDT test of welds and seems.

- Steam and Hot Fluids. Pipe work insulation and cladding to a high standard.

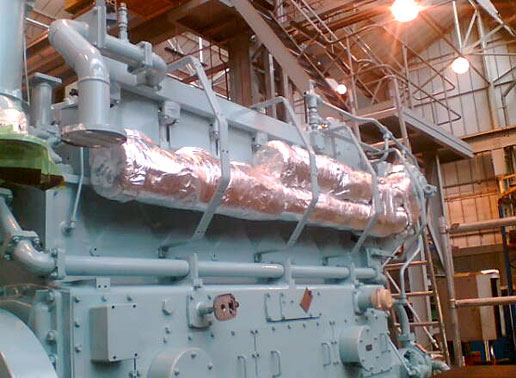

- Exhaust Systems. Insulation of exhaust silencers and pipe/ductwork on all types of engines, including diesel and gas internal combustion units, and gas turbines. Using high temperature insulants, either "permanently" fixed and covered with custom made metal cladding, or in the form of easily removable flexible jackets we are able to help you to control engine room temperatures for better operator conditions and engine efficiency, with the added benefit of reducing noise break out.

- Process Equipment. We have recently undertaken the insulation and cladding of new large-scale industrial coffee roasting. Finished to meet the rigorous hygiene standards of the food industry.

With the back-up and support of leading insulation manufacturers we can come up with solutions to meet your specific requirements. Contact us today for High Temperature Insulation in Nottingham and Peterborough